關於我們

About Us

Facilities / Manufacturing

Horsing is located in suburbs of Taichung city, Taiwan, 10 minutes from Taichung Airport and 30 minutes from bullet train station (HSR). In 2010, we are pleased to have the inauguration of a new 5-floor building. Our 80,000 ft² facility includes Customer Service, Product Design and Development, Graphic Center and CNC Tooling, Gel Compound, Production Area, Clean Room for Coating Process, QC and Packaging, Die Cutting, Warehouse and Shipping and is led by a highly skilled and dedicated team of employees.

Process

Horsing is located in suburbs of Taichung city, Taiwan, 10 minutes from Taichung Airport and 30 minutes from bullet train station (HSR). In 2010, we are pleased to have the inauguration of a new 5-floor building. Our 80,000 ft² facility includes Customer Service, Product Design and Development, Graphic Center and CNC Tooling, Gel Compound, Production Area, Clean Room for Coating Process, QC and Packaging, Die Cutting, Warehouse and Shipping and is led by a highly skilled and dedicated team of employees.

Process

*Molded injection and cast silicone gel

*Self-adhesive and Non-adhesive silicone gel coating/sheeting

*Molded injection and cast TPE gel

*Molded injection and cast Polyurethane gel and foam.

* TPE gel coating/sheeting

*Vacuum and shaping

*Molded Memory Plastic (High-flexible, supportive Polyurethane). A polymeric smart material that has the ability to return from a deformed state (temporary)

*Gel screen print

*In-house CNC molding system

*Sonic Welding and Heat Seal

*Die Cutting / Kiss Cutting

Material Capabilities

*Dual-durometer combos Molded gel/foam with 2 durometers by 2 colors

*Combine molded gels with foams/Air Mesh

*Molded gel/foam behind fabrics/Velcro

*Multi-material marriage : Insert (soft or stiff) molding of components

*Soft TPE gel with stiff Polypropylene

*Gel formula with infrared , ceramic, chitonsan, silver nano-powder

*Lycra, micro fiber, webbing with gel coated and pattern screen printed.

* Compression sheet made of silicone gel with fabric covered one-sided or 2-sided.

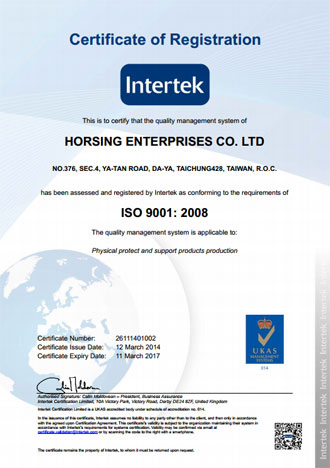

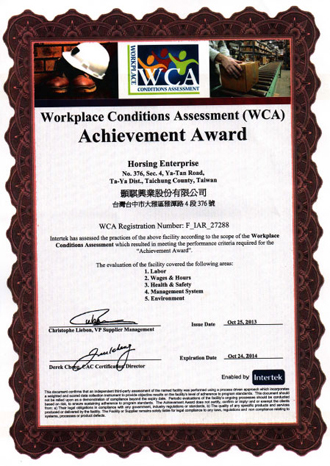

Quality System

Horsing is an ISO-9001certificated and a regularly audited factory by our partners or the independent agencies they appointed. We make quality the cornerstone of our philosophy and business and manufacture to the highest standards and extensively test our gels and finished parts to guarantee consistent quality. That means you can count on reliable performance from every Horsing shipment every time.

Staff

We recognize that our people are our greatest resource and the key to the success of our customers. Our professional and experienced sales and engineering team works closely with customers to offer tailored designs and materials to each specific product or application. We can provide CAD drawings, tooling, prototypes and assistance through the design process to ensure complete customer satisfaction and quality products.

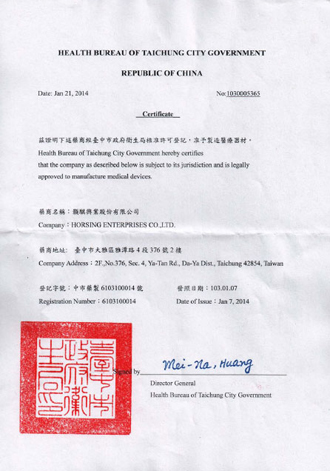

Certification

History

Founded in 1990, Horsing Enterprises started with manufacturing snow boots and jockey boots with the cutting-edge innovation, Slush Molding. With this technology Horsing was able to cater to one of the most demanding market in the world – Japan and had constantly met the high requirements of quality, lead time, service and management for the Japanese market.

In 1997, Horsing made a strategic decision to transfer all equipments to the shoe factory located in Vietnam owned by its co-founder, Trivict Co. Ltd. who has continued to be one of the leading vendors in the world for vulcanized, cemented, Goodyear welted, stitch-down, San Crispino construction shoes.

Based on its extensive knowledge in shoe making and good connections in shoe industry, Taiwan Horsing stepped out to research for new opportunity and technology to serve the footwear industry, which resulted in a top-notch injection system called micro-injection 3D labels Up to date, labels and accessories for shoes, garments and bags are still part of Horsing business and investment. Horsing has been an approved and assigned accessory supplier for two giant footwear groups, Nike and Adidas, since 2001.

In 1999, one major event occurred. Nike renounced any usage of PVC materials because it assumes the social responsibility of environmental protection. In searching for a substitute material, Horsing entered silicone gel applications with the help and support from Shin-Etsu Chemical Co., Ltd., the world’s largest supplier of semiconductor silicones, and successfully developed a series of dual-density silicone insoles and heel cups for foot care and orthopedic industry. We have become a valuable player in multiple silicone gel applications serving the industries of Foot Orthopedics, Skincare (scar sheeting) and Braces and Supports and so on meeting the requirements of CE medical class I level since the turning point in 1999.

In 2005, Horsing and PolyGel LLC, a pioneer of gel-based technologies and consumer

healthcare products in USA, became joint venture which ushered in the brand-new era of advanced mineral-oil based TPE gel technology and products. With this new material and technology, the east and west fusion started developing and producing a whole range of TPE gel products serving the foot care orthopedic, hand therapy and skin care markets worldwide. Under the assigned job function and sales territory, Horsing and PolyGel have worked collaboratively for the goal of bringing wellness solutions to people all around the globe.

In 2009, Gelsmart brand (www.gelsmart.com.tw) is registered and operated in Asian area. Distributions have covered Taiwan, China, Korea, Japan, Singapore, Malaysia, Thailand, Philippine, etc. Gelsmart America and Europe are under Polygel’s operation.

In 2010, we are pleased to have the inauguration of a new 5-floor building. Our 80,000 ft² facility includes Customer Service, Product Design and Development, Graphic Center and CNC Tooling, Gel Compound, Production Area, Clean Room for Coating Process, QC and Packaging , Die Cutting, Warehouse and Shipping, etc.

In 2010, we endeavored to incorporate Polyurethane (PU) gel and PU foam into its footcare lines which has made the marriage of gel and foam possible and successful.

In 2012, a new division is established to provide molded gel and foam pads to designers of orthotics and sports medicine products and turn their requirements for cushion, compression, support, comfort, protection, stabilization, anti-friction, anti-vibration, and anti-slide into reality.

Our expertise has allowed us to create products in molded silicone gel, TPE gel, Polyurethane gel and Polyurethane foam and their various combinations. Our gel/foam formulas are all non-toxic and non-allergenic and will not support bacterial growth. Horsing has utilized sophisticated R&D and manufacturing capabilities to develop the most advanced, eco-friendly and innovative materials for the healthcare market. We provide not only private label service but also OEM & ODM service.

Copyright by Horsing Enterprises Co., Ltd. 2020. All rights reserved.